Custom T-Box

Specialized boxes of packaging are referred to as custom T-Boxes. They are rectangular in shape with a top that can either be folded down. They’re constructed with paperboard, cardboard, or plastic. They can print boxes with logos and whatever design is desired. You can incorporate our custom boxes to pack electronics, cosmetics, jewelry, food, and medicines. Subsequently, we offer customised sizes 10x5x2 inches, 12x6x3 inches, 15x10x5 inches, etc.

Get Your Custom Quote

Share your box details and we will send your price.

Applications Of Custom Printed T-Boxes

Electronics

The electronics industry utilizes Custom T-box packaging. Custom inserts are necessary to hold devices such as Apple AirPods and Samsung Galaxy Buds. They are shipped securely in a box with foam padding and a tuck-end closure.

Branding and design: Offset printing, flexography, and digital printing. Common materials include paperboard and corrugated cardboard. The packaging is so designed that shocks do not damage it and fall. Some Electronics companies also use Custom T-Box packaging for accessories, including chargers and headphones.

Cosmetics and Beauty Products

Cosmetic brands promote their products using Custom T-box packaging. Urban Decay’s Naked Palettes mock-up custom inserts and mirrors for Benefit’s Brow Kits. The tuck-end closure protects the products inside.

Offset printing, Screen Printing, and hot foil stamping add a premium feel. The base is made of paperboard, corrugated cardboard, and PVC inserts to make it feel special. The external design is an image of the brand. Certainly, T shaped boxes also helps avoid damaging delicate cosmetic items.

Jewelry and Accessories

Custom T-Box packaging provides an edge of sophistication for jewelry and accessory brands. Custom inserts and velvet pouches for Fossil Watches and Ray-Ban Sunglasses. The tuck-end closure holds the products in place. Branding is done using offset printing, flexography, and digital printing.

A luxurious unboxing experience includes paperboard, corrugated cardboard, and velvet pouches. Everything is packaged to feel like a special gift. T-shaped packaging also protects delicate pieces of jewelry from scratching and damage.

Food and Beverage

Food and beverage manufacturers commonly use custom T-box packaging for gifting. Starbucks Coffee Gift Sets and Godiva Chocolate Gift Boxes use custom inserts and food-rated liners.

A tuck-end closure ensures the freshness of products. Flexography, offset printing, and digital printing are used for branding. Paperboardoard, corrugated cardboard, and food-grade li are used for safe packaging.

The packaging keeps the products fresh and full of flavour. Furthermore, these printed boxes makes the unboxing experience unique for the customers.

Pharma & Health Care

Pharmaceutical and healthcare companies use custom T-box packaging to package and ship medical products. Two products currently on the market with custom inserts and tamper-evident seals are Johnson & Johnson’s first aid kits and Neutrogena’s Skincare Sets.

The ends are welded for easy shipping. Branding and labeling use offset printing, flexographic printing, and electronic printing. The regulatory needs must be met: paperboard, corrugated cardboard, and PVC inserts. The packaging is created so that the products are not damaged or contaminated. Printed packaging also scampers the counterfeiting and tampering.

Designing Custom T-Shaped Boxes

Step 1 — Identifying Packaging Requirements

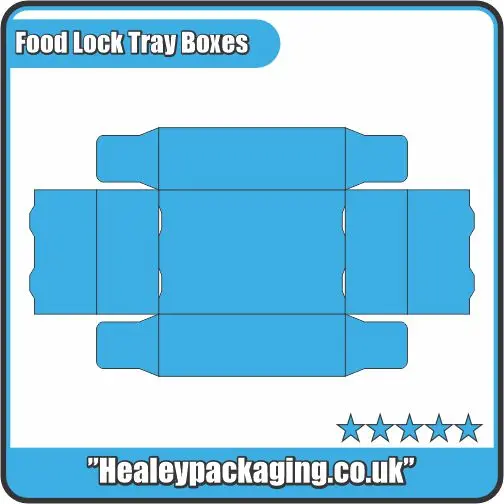

Companies should begin by determining their packaging needs, such as size, weight, and shipping. Next, they should design the package using CAD software to create a template for the T-Box.

Step 2: Designing the T-Box

This includes selecting the style and dimension, the substance from which the box is fabricated, and printing options such as the title, color, and graphics.

Step 3: Choose Your Materials and Printing Options

Companies choose the material for a T-Box, whether paperboard, cardboard, or plastic. Based on the Text design and the quantity to be printed, they decide on the type of printing (flexography, offset printing, digital printing, etc.) required.

Step 4: Finalizing the Design

In the end, businesses take that design, consider what will fit within their branding, and finalize their packaging,

Step 5: Choosing the Right Size

The last step is to select the size of the T-box. However, it significantly depends on the product design and size. In the market, you will find standard dimensions such as 10x5x2 inches, 12x6x3 inches, and 15x10x5 inches. By following these steps, businesses can design printed boxes that fit the product to be packed and presented.

Get Personalised Printed T-Boxes Online

For high-end custom T-shaped packaging, contact Healey Packaging in the UK. Healey Packaging has the expert designer team and offers tailor-made solutions. It employs high-quality materials and state-of-the-art printing technology. Send us an email at help@healeypackaging.co.uk to get an instant quote.

| Dimension (L + W + H) | All Custom Sizes & Shapes |

|---|---|

| Quantities | No Minimum Order Required |

| Paper Stock | 210gsm, 250gsm, 280gsm, 300gsm, 350gsm, 420gsm, 460gsm, 500gsm, Bleach Card (SBS), Eco-Friendly Kraft, E-flute Corrugated, Bux Board, etc. |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scoring, Perforation |

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 7 – 10 Business Days, RUSH |

| Shipping | FLAT |

No FAQs available for this product.

Why Brands Trust Us

We are not just box manufacturers. We help brands package smarter, ship safer, and sell better, without unnecessary complexity.

- Packaging Specialists Industry-focused structures, not generic templates.

- Low MOQ Support Start small, scale confidently.

- Material-First Engineering Right board, right strength, right finish.

- UK & Global Fulfilment Flat packed, secure, and delivery-ready.

Our Process

Share your product size, quantity, and use-case.

We recommend structure, material, and finish.

Approve dieline or sample before production.

Manufacturing, quality check, and delivery.