1-2-3 Bottom Display Lid Boxes

The 1-2-3 Bottom Display Lid Box is an effective package. It has a special shape, it’s got a door that opens to expose the products. It is perfect for showing items such as makeup, jewellery and gadgets. The box is simple to build, it is 1-2-3 bottom. It offers great protection and visibility for goods which is the best option for the companies looking for effective packaging solutions. There are multiple sizes and custom shapes.

Get Your Custom Quote

Share your box details and we will send your price.

Introduction to 1-2-3 Bottom Display Lid Boxes

1-2-3 Bottom Display Lid Boxes are various carton boxes which are widely used in the shop to display many products. These boxes are famous for the characteristic and attractive pattern. This pattern is customisable and branding with multiple designs and colours. These boxes usually consist of a box, a hinged (or removable) lid, and a space where the product is packed.

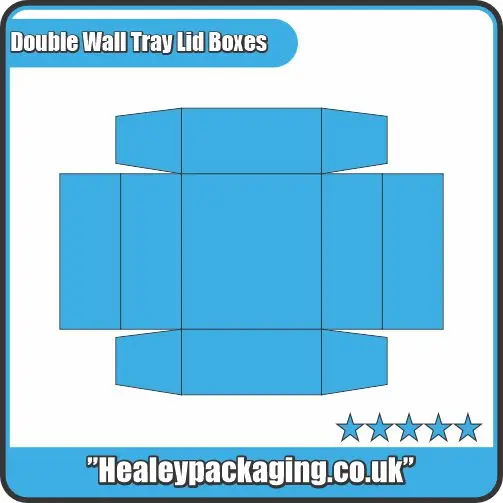

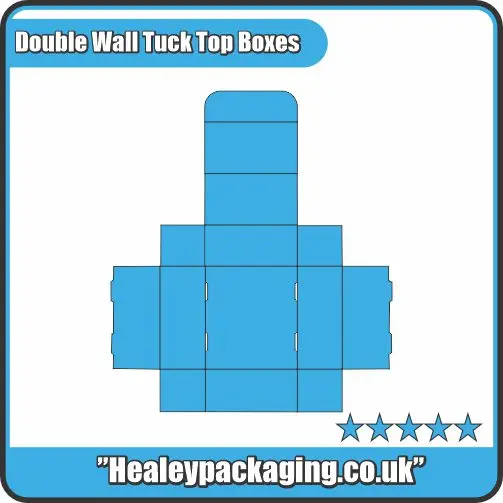

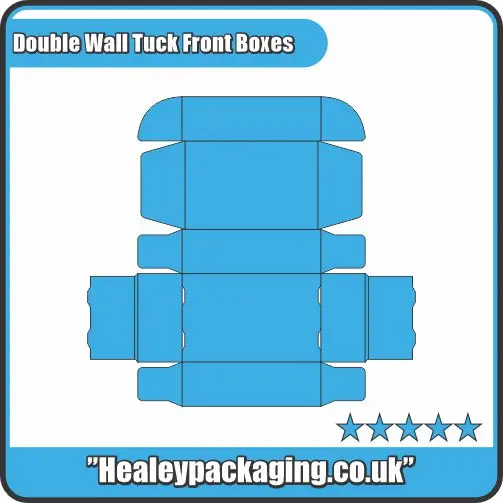

2. Structure of 1-2-3 Bottom Display Lid Boxes

1-2-3 Bottom Display Lid Boxes have three main parts. Those are the bottom, sidewalls and the top. Base : this is the box’s biggest region. It has a rigid form and the weight of the box’s contents and the sides of it.

Cardstock or corrugated board make the sidewalls. They surround and isolate the product from others. The lid is handy bigger than the base. Sometimes it’s folded on hinges and pinched into place on the floor. This keeps the product in front of customers’ eyes.

3. Printing Methods:

You can make the 1-2-3 Bottom Display Lid Boxes many ways. These two are the most used: digital printing and offset printing.

Short-to-medium runs:

Digital printing is famous for this kind of printing. It is very fast, clear and crisp and of good quality. Printing by offset, meanwhile, works better for larger runs. It yields crystal-clear texts, better colour matching and higher general prints.

4. 1-2-3 Bottom Display Lid Boxes Design Steps

1-2-3 Bottom Display Lid Boxes, You Need To Follow A Few Processes To Design Good-Looking Effective Packaging. These steps include:

Step 1: Concept Development

So that you can have an immediate idea in the packaging design:

Choose your audience and desired aesthetics.

You can create self-image based on the brand, the product’s features and the message you are trying to promote.

Step 2: Sketching and Prototyping

Create the prototype of the box layout and the actual cardboard packaging mock-up.

Try different shapes, sizes, and positioning suitable for showing the actual product.

Final modification of the design based on comments and the test performance of the design.

Step 3: Die Line Creation

Have exact, actual dissection, using the box provided’s shape and dimensions.

- Verify that the folds, cuts and scores in the lines of the die match up.

- Add any modifications, like windows or tab closures.

Step 4: Graphic Design

Create beautiful pictures for the box. They are the product, the company, the tagline.

It needs cheerful shades, attractive photos and readable words. This attracts the attention of the users. Make sure the design fits the brand and speaks to the scale of value provided.

Step 5: Printing

Select the right print process according to design requirements and number of prints.

Seek out a printer to make the actual boxes as mockups. Double-check the printed proofs and, if they haven’t been well-checked, modify accordingly.

Step 6: Assembly and Testing

Fix the box pieces together, secure the joint. Don’t forget to test the toy in all of its ways.

Sort the supplies by type. Build the assembled box in good shape, sturdy and simple to use.

Create the design changes you need to improve performance and looks.

Step 7: Mass Production

Finish designing the product for mass production. Contact Healey Packaging to create the box and purchase in bulk. Check that the end product is high-quality and smooth.

Where to get 1-2-3 Bottom Display Lid Boxes?

Bottom Display Lid Boxes 1-2-3 Bottom Display are one of the most interesting and multipurpose boxes. The people who would want this packaging, they can send their order o Healey Packaging. We provide free design assistance along with free shipping. Contact us at +44 1442781174.

| Dimension (L + W + H) | All Custom Sizes & Shapes |

|---|---|

| Quantities | No Minimum Order Required |

| Paper Stock | 210gsm, 250gsm, 280gsm, 300gsm, 350gsm, 420gsm, 460gsm, 500gsm, Bleach Card (SBS), Eco-Friendly Kraft, E-flute Corrugated, Bux Board, etc. |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scoring, Perforation |

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 7 – 10 Business Days, RUSH |

| Shipping | FLAT |

No FAQs available for this product.

Why Brands Trust Us

We are not just box manufacturers. We help brands package smarter, ship safer, and sell better, without unnecessary complexity.

- Packaging Specialists Industry-focused structures, not generic templates.

- Low MOQ Support Start small, scale confidently.

- Material-First Engineering Right board, right strength, right finish.

- UK & Global Fulfilment Flat packed, secure, and delivery-ready.

Our Process

Share your product size, quantity, and use-case.

We recommend structure, material, and finish.

Approve dieline or sample before production.

Manufacturing, quality check, and delivery.