Flat Pack Boxes

Flat pack boxes are usually chosen for one simple reason: space. When storage costs matter and assembly time can’t be wasted, a box that arrives flat and builds quickly becomes the sensible option. Our custom flat pack boxes are made for that reality. Healey Packaging has spent over five years supplying UK businesses with flat packed boxes that store neatly, assemble cleanly, and still protect products properly once they’re built.

Share your box details and we will send your price.Get Your Custom Quote

Custom Flat Pack Boxes Built for How Business Actually Ship

Flat packing isn’t about cutting corners. It’s about control. When boxes ship flat, you move more units per pallet, store more stock in less space, and reduce handling damage before the box is even used. At Healey Packaging, we design flat pack cardboard boxes around how they’ll be stored, assembled, and filled, not just how they look in a mockup.

Our team has been producing packaging for over a decade, supplying thousands of flat packed boxes across the UK for retail, logistics, gifting, and eCommerce operations.

Why Flat Pack Packaging Makes Commercial Sense?

Flat pack packaging boxes are chosen for one reason first, efficiency. They lower shipping volume, which directly reduces transport costs. They also simplify storage, especially for seasonal or bulk packaging runs.

From flat pack boxes for moving to flat pack gift boxes used in retail launches, the benefit stays the same: less wasted space, fewer damaged cartons, and faster packing lines.

Material Options for Premium or Natural Looks

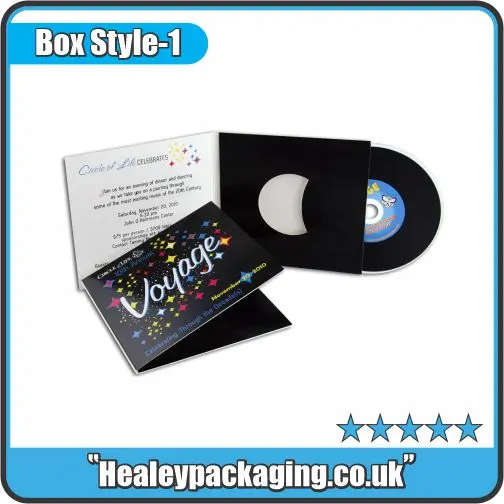

Most flat pack boxes are produced using sturdy cardboard, but material choice still matters. We offer white flat pack boxes for clean branding, black flat pack boxes for premium presentation, and kraft board for brands that prefer a natural finish.

For heavier items or drawer-style packaging, flat pack drawer boxes provide structure while still shipping folded. Each board thickness is matched to product weight, stacking pressure, and intended reuse.

Flat Pack Boxes Sized to Your Product, Not a Catalog

Flat pack boxes come in more than “small” or “large.” We regularly produce A4 flat pack boxes for documents and kits, compact formats for cosmetics, and extra large flat pack gift box sizes for hampers and bundled products.

Whether you need flat pack storage boxes for internal use or flat pack boxes with lids for retail, sizing is adjusted to reduce void fill and prevent movement during transit.

Designing for the Fold: Where Structure Meets Brand

Flat pack box design needs to work before it needs to look good. We start with structure, fold lines, and assembly flow, then apply print. Printed flat pack boxes can be produced using digital print for short runs or offset for larger volumes.

Branding stays consistent across panels so the box still looks intentional once assembled. If you already have a flat pack box template, we can work from it or refine it for better performance.

Balancing Stock, Space & Speed with Flat Pack Boxes

Flat pack packaging is widely used across industries. Retailers rely on flat pack boxes wholesale to manage stock peaks. Logistics teams use flat pack boxes for moving and storage. Brands choose flat pack gift boxes to balance presentation with shipping efficiency.

They’re also popular with subscription brands and eCommerce sellers who want packaging that arrives intact and assembles quickly at fulfilment.

Sustainable by Default: The Flat Pack Advantage

Flat packed boxes are often more sustainable by default. Shipping flat reduces transport emissions, and cardboard materials are widely recyclable. We offer FSC®-certified board options and water-based inks where suitable, without overstating claims.

For many businesses, flat packing is one of the simplest ways to reduce packaging waste without redesigning the entire supply chain.

Clarity from Proof to Dispatch: Our Production Roadmap

Every order follows a straightforward path. We confirm size and structure, share a proof, produce samples if needed, then move into production. Flat pack boxes wholesale orders are quality-checked for fold accuracy, print alignment, and stacking strength before dispatch.

Lead times typically range from 10 to 14 working days across the UK.

| Dimension (L + W + H) | All Custom Sizes & Shapes |

|---|---|

| Quantities | No Minimum Order Required |

| Paper Stock | 210gsm, 250gsm, 280gsm, 300gsm, 350gsm, 420gsm, 460gsm, 500gsm, Bleach Card (SBS), Eco-Friendly Kraft, E-flute Corrugated, Bux Board, etc. |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scoring, Perforation |

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 7 – 10 Business Days, RUSH |

| Shipping | FLAT |

Are flat pack boxes easy to assemble?

Yes. Our designs are made to assemble quickly without forcing folds or excessive taping.

Can you print branding on flat pack boxes?

Yes. Printed flat pack boxes are available with clean alignment and consistent colour.

Do you supply flat pack boxes in bulk?

Yes. Wholesale and bulk quantities are available for UK businesses.

Are eco-friendly materials available?

FSC®-certified board can be supplied on request.

Are flat pack boxes suitable for retail display?

They can be, especially when designed with lids or drawer-style structures.

Explore Our Premium Packaging Options

Mix and match materials, printing methods, inks, finishes, and add-ons.

Natural Brown Kraft

SBS / Bleach Card

Black Kraft / Black Card

Digital Print

Offset Print

Scodix Enhancement

UV Print

CMYK Process Inks

Pantone Spot Inks

Screen Printing

Soy / Vegetable Inks

Matte Lamination

Gloss Lamination

Soft-Touch Coating

Spot Gloss UV

Foil Stamping

Embossing

Debossing

Die-Cut Windows

Why Brands Trust Us

We are not just box manufacturers. We help brands package smarter, ship safer, and sell better, without unnecessary complexity.

- Packaging Specialists Industry-focused structures, not generic templates.

- Low MOQ Support Start small, scale confidently.

- Material-First Engineering Right board, right strength, right finish.

- UK & Global Fulfilment Flat packed, secure, and delivery-ready.

Our Process

Share your product size, quantity, and use-case.

We recommend structure, material, and finish.

Approve dieline or sample before production.

Manufacturing, quality check, and delivery.