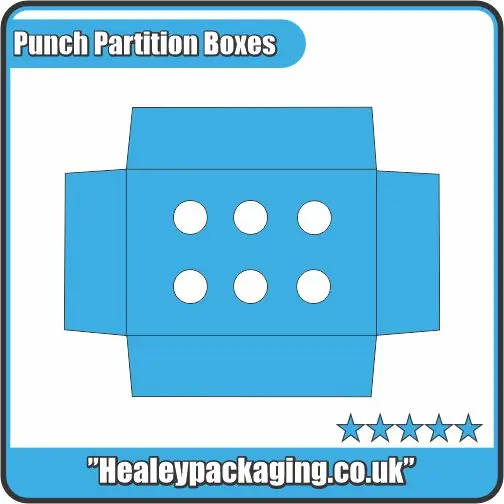

Punch Partition Boxes

Custom punch partition boxes benefit businesses. Usually, they contain more than one item in a single container. These boxes help design removable partitions inside the box to create separate sections for each product. These sections can be tailored to fit various sizes and shapes according to the item’s condition. They are useful for e-commerce, retail, and manufacturing markets. They reduce items while improving their presentation, making them a great packaging solution.

Get Your Custom Quote

Share your box details and we will send your price.

Uses of Punch Partition Boxes

For Glassware and Pottery

Glassware and pottery fail to pack into normal parcels. This calls for a separate packaging method. The punch partition ensures that each member has a net-tight fit, leading to no possibility of breakages and preventing them from an early break before they reach customers.

Therefore, for a company that deals with artisanal glass or pottery, you can design the boxes to be not only secure but also visually appealing. In this way, customers will feel more secure about what they will be receiving.

For Cosmetics and Skincare Products

Many people rely on secure, pretty packaging wraps to protect beauty-related products like lotions, serums, and makeup. Punch partition boxes are also used to organise individual sections of such products indoors, preventing smoke and scratches due to movement or internal breakages.

The entire packaging setting also feels luxurious, and customers enjoy the wonderful unboxing experience. These boxes are trendy because of their high perception when packed for gift sets and subscription businesses.

For Confectionery

Confectioneries such as chocolates, truffles, and macarons contain peculiar structures that need to be protected. Punch partition boxes isolate pieces from one another, thereby protecting them from smudging or breaking.

This type of packing is appropriate for festive occasions, weddings, and other functions. It serves its purpose and also adds a little eye candy for the customer. Therefore, customers relate the brand to a greater deal of quality and care.

For Electronics Accessories

Like small electronic implements chargers, earphones, and adapters strangely leave people without them but are very important to handle thoroughly.

Punch partition boxes accommodate each accessory of the specific products within separate compartments, thus ensuring no tangling and damage during transit or travel.

Typically, the retailers use the boxes to bundle products or make organised kits for customers. The packaging becomes more convenient as now the compartments make access to searching and storing easy. Customers appreciate having the nice organisation these boxes provide.

Steps to Designing Custom Punch Partition Boxes

There are several steps to creating custom packaging. At each stage, the packaging must protect the product while aligning with the brand identity.

Get the Product Right

Take first things first, and check the size, weight, and fragility of the respective items under consideration for packaging. Products with a rather fragile composition need tight compartments for surrendering any movement. Heavy items would be best with thick materials and much stronger dividers to ensure safety.

Choose the Right Material

Material matters a lot when it comes to the box’s guaranteed strength and durability. Corrugated cardboard’s great strength makes it the ideal choice for heavier goods, whereas kraft paper works for eco-friendly conscience brands.

Choosing the right material ensures that your product remains safe and stays true to your brand values.

Focus ON Branding

Custom punch partition boxes are a good way to show your brand. Add your logo, brand colours, and taglines to your outside design. Good printing will make your packaging stand out. Good branding creates an impression and makes the customer more loyal to your products.

Now Test For Practicality

It should be easy to use and suitable for shipping. Make sure that the partition holds the products snugly. Test prototypes before confirming that the box can support the weight and dimensions of the items inside. Practicality is very important to assure the products’ safety and the consumer’s comfort.

Has Your Personal Touch

Think about how the design could be personalised to enhance the customer experience. Would a thank-you note, user guide, or promotional insert be appropriate for a division?

These small elements can add spice to the unboxing experience while also maintaining a positive impression on your customers.

Why Choose Healey Packaging?

Healey Packaging is renowned for its custom packaging solutions. It specialises in manufacturing customized, high-quality punch partition boxes and is adept at understanding and designing packaging according to the client’s business needs. Our expert designers design the packaging following your company theme. You can also order custom seal end boxes.

| Dimension (L + W + H) | All Custom Sizes & Shapes |

|---|---|

| Quantities | No Minimum Order Required |

| Paper Stock | 210gsm, 250gsm, 280gsm, 300gsm, 350gsm, 420gsm, 460gsm, 500gsm, Bleach Card (SBS), Eco-Friendly Kraft, E-flute Corrugated, Bux Board, etc. |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scoring, Perforation |

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 7 – 10 Business Days, RUSH |

| Shipping | FLAT |

No FAQs available for this product.

Explore Our Premium Packaging Options

Mix and match materials, printing methods, inks, finishes, and add-ons.

Natural Brown Kraft

SBS / Bleach Card

Black Kraft / Black Card

Digital Print

Offset Print

Scodix Enhancement

UV Print

CMYK Process Inks

Pantone Spot Inks

Screen Printing

Soy / Vegetable Inks

Matte Lamination

Gloss Lamination

Soft-Touch Coating

Spot Gloss UV

Foil Stamping

Embossing

Debossing

Die-Cut Windows

Why Brands Trust Us

We are not just box manufacturers. We help brands package smarter, ship safer, and sell better, without unnecessary complexity.

- Packaging Specialists Industry-focused structures, not generic templates.

- Low MOQ Support Start small, scale confidently.

- Material-First Engineering Right board, right strength, right finish.

- UK & Global Fulfilment Flat packed, secure, and delivery-ready.

Our Process

Share your product size, quantity, and use-case.

We recommend structure, material, and finish.

Approve dieline or sample before production.

Manufacturing, quality check, and delivery.