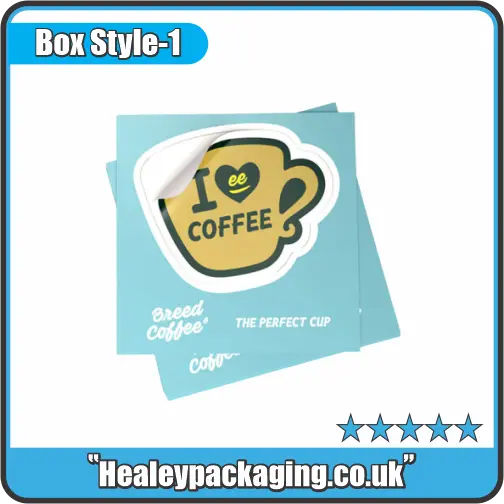

Custom Stickers And Labels

Stickers and labels only work if they apply cleanly and stay put. Curling edges, poor adhesion, or ink rub-off cause problems fast. We supply labels designed to apply smoothly, remain readable, and perform reliably across handling, storage, and end-use conditions rather than failing after first contact.

Custom Stickers and Labels That Actually Work for Your Brand

At Healey Packaging, we’ve been printing custom stickers and labels long enough to know — they’re not just decoration. They’re tiny, hard-working storytellers. A good sticker can hold a customer’s eye, make a product feel handmade, or turn a plain box into something they remember.

We print for all sorts of UK brands — from small candle makers to food producers and fashion labels. Some need gloss vinyl that holds up outdoors. Others want matte paper with that earthy, artisan feel. Whatever you’re selling, your label should make sense for your product, your shelf, and your customer.

The Role Stickers Play in Packaging

A lot of people underestimate the job a sticker does. It’s the seal that keeps a box closed, the branding that tells buyers who made it, and sometimes the difference between “looks cheap” and “looks professional.”

We’ve helped businesses create everything from holographic stickers for limited runs to food labels printed on greaseproof paper for bakeries and cafes.

If you’re rebranding or just starting out, we’ll help you choose the right size, adhesive, and finish — practical stuff that decides whether your label looks premium or peels after a week.

Bespoke Sticker Printing Options

Printing isn’t one-size-fits-all. Short runs go digital; bulk orders use offset or flexo. Each method is matched to your artwork, not the other way round.

Here’s what you can do with your design:

- Add foil or metallic finishes for extra shine — gold, silver, rose gold, or holographic.

- Choose materials like vinyl for waterproof durability or kraft paper for an eco touch.

- Play with textures — gloss for pop, matte for subtlety, soft-touch for something in between.

- Custom shapes cut exactly to your logo or design.

Every print is colour-matched to your brand palette, ensuring your stickers stay consistent across every batch and product line.

Small Details, Big Impact

Think about it — people touch your packaging before they taste, smell, or use what’s inside. That first contact matters. Our custom labels don’t just add branding; they help shape perception.

A logo sticker on a candle lid, a clear label on a skincare bottle, or a custom printed label sealing a food carton — it’s all part of your story.

And if you’re running seasonal campaigns, we can switch up your artwork fast for Christmas stickers, Valentine’s promos, or special edition product drops.

Eco-Friendly Label Options

We’re all trying to do better for the planet, and packaging shouldn’t be an exception.

We offer:

- FSC®-certified paper stocks

- Biodegradable or recyclable liners

- Water-based and soy inks

These options keep your eco-friendly packaging consistent from box to label. If you’re already using sustainable boxes or bags, we’ll make sure your stickers match the message.

Why Brands Across the UK Choose Healey Packaging

Because we get it. You want consistency, reliability, and that small-firm flexibility big suppliers often forget. We run design checks before printing, send proofs for approval, and make sure every order — whether 500 or 50,000 — looks the way it should.

Most clients stick with us (no pun intended) because we treat every run like it’s going on a shop shelf tomorrow.

Common Sticker and Label Uses

- Food & beverage labels – moisture-resistant and compliant with UK/EU packaging rules

- Beauty & candle brands – heat-resistant, oil-proof, and elegantly printed

- Retail & clothing tags – logo stickers, price labels, or folded swing tags

- Corporate or event stickers – for packaging, swag bags, or giveaways

Explore Custom Stickers And Labels Styles

Pick a style, then customise size, board, finish, and print.

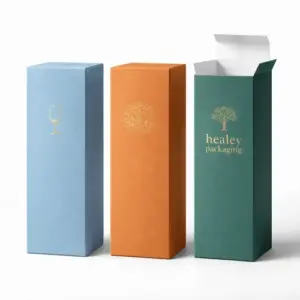

Explore Our Premium Packaging Options

Mix and match materials, printing methods, inks, finishes, and add-ons to build packaging that feels completely on-brand. Start with the material, then move through print and finishing to see what fits your product best.

Natural Brown Kraft

SBS / Bleach Card

Black Kraft / Black Card

Digital Print

Offset Print

Scodix Enhancement

UV Print

CMYK Process Inks

Pantone Spot Inks

Screen Printing

Soy / Vegetable Inks

Matte Lamination

Gloss Lamination

Soft-Touch Coating

Spot Gloss UV

Foil Stamping

Embossing

Debossing

Die-Cut Windows

Other Categories

Explore related packaging categories used by similar brands.

Trusted on Trustpilot

Real customer feedback from businesses across the UK.

FAQs

Answers to common questions about sizing, materials, inserts, printing, and delivery.

Yes — we cut to any shape and print with foils, laminates, or textures to match your brand.

We have vinyl and laminated options built to handle moisture and rough handling.

Absolutely. We’ll print short runs digitally — great for testing, rebranding, or pop-up events.

Yes, we offer recyclable, biodegradable, and FSC®-approved label papers and films.

Usually 7–10 working days after artwork approval, but rush options are available.