Introduction – It’s Not Just About Getting Boxes on Time

When brands talk about packaging supply challenges, the conversation usually starts with lead times and pricing. Getting boxes delivered on schedule and within budget feels like the obvious priority. But in practice, packaging supply consistency is far more difficult, and far more damaging when it goes wrong.

Inconsistent packaging creates operational friction, undermines brand trust, and quietly increases costs over time. For brands relying on custom packaging solutions, variations in colour, material strength, sizing, or finish may seem minor on paper, but customers notice them immediately. Internally, these inconsistencies ripple through fulfilment, retail display, and quality control processes.

For growing eCommerce brands and retailers, consistency is not a “nice to have”. It is a foundation for reliable operations and long-term brand credibility.

What Does “Consistency” Mean in Packaging Supply?

Consistency in packaging supply goes beyond receiving boxes that look similar. It means maintaining reliability across every production and delivery cycle, especially when working with custom printed boxes that must meet exact visual and structural standards.

Key elements of packaging quality consistency include:

- Material quality: consistent thickness, strength, and surface finish

- Colour accuracy: reliable reproduction across print runs

- Structural integrity: precise sizing, folds, and assembly

- Supply reliability: predictable delivery timelines and reorder performance

True consistency ensures that packaging performs the same way today as it did six months ago, regardless of volume or reorder frequency.

Why Consistency Is So Hard to Maintain?

Multiple Production Variables

Packaging production involves many variables that can shift over time:

- Paper sourced from different batches

- Ink formulation changes

- Machine calibration differences between runs

Without tight controls, these small variations add up, leading to visible differences between orders.

Global Supply Chain Disruptions

Packaging supply chain issues have become more common due to:

- Raw material shortages

- Longer shipping routes

- Supplier substitutions under pressure

When materials are swapped to meet deadlines, consistency often suffers first.

Supplier Switching

Switching suppliers to chase lower prices or shorter lead times introduces risk:

- Specifications may not transfer accurately

- Historical production data is lost

- Quality benchmarks reset unintentionally

Even well-documented specs rarely translate perfectly without continuity.

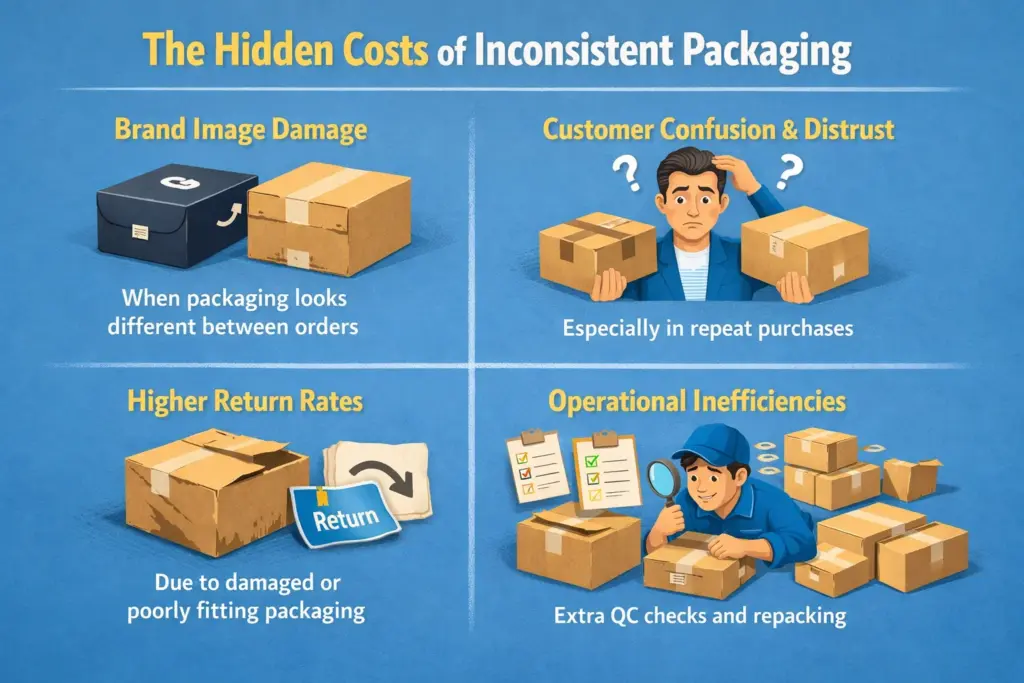

The Hidden Costs of Inconsistent Packaging

The cost of inconsistency is rarely limited to packaging itself.

- Brand image damage when packaging looks different between orders

- Customer confusion and distrust, especially in repeat purchases

- Higher return rates due to damaged or poorly fitting packaging

- Operational inefficiencies, including extra QC checks and repacking

Over time, these hidden costs often exceed any short-term savings achieved through cheaper suppliers.

Inconsistency often leads to increased returns, repacking, and additional quality checks. Brands using corrugated packaging for shipping are particularly affected when material strength or sizing varies between runs, increasing the risk of damage in transit.

Colour Consistency – A Major Pain Point for Brands

Colour inconsistency is one of the most common complaints in custom packaging supply.

Key reasons colours shift between runs include:

- Differences between Pantone and CMYK reproduction

- Variations in substrate colour and absorbency

- Lighting conditions during production and inspection

Without proper colour management and proofing, even approved artwork can produce inconsistent results.

Colour proofing and controlled print processes are essential for brands that rely on visual recognition and shelf presence.

Material & Structural Inconsistencies

Even when packaging looks acceptable, hidden material differences can cause serious problems.

Common issues include:

- GSM variation, affecting box strength

- Flute strength differences in corrugated packaging

- Sizing tolerances that impact fit and stacking

Small changes in material or structure can lead to crushed boxes, higher shipping damage, and poor pallet stability.

How Inconsistent Packaging Affects eCommerce & Retail?

eCommerce Impact

For eCommerce brands, inconsistency often results in:

- Increased shipping damage

- Poor unboxing experiences

- Negative reviews and reduced repeat purchases

Customers expect the same experience every time. Variations break that expectation.

Retail Impact

In retail environments, inconsistency creates visible problems:

- Shelf misalignment

- Uneven presentation across locations

- Compliance risks when packaging dimensions or information change

Retail buyers expect uniformity. Inconsistent packaging can jeopardise listings and relationships.

Why Low Price Often Leads to Low Consistency?

Low pricing frequently comes at the expense of control.

Common cost-cutting practices include:

- Substituting materials without notice

- Reducing quality control steps

- Rushing production to meet volume targets

While the unit cost may drop, the overall cost of inconsistency increases sharply.

How to Achieve Consistency in Packaging Supply?

Standardise Specifications

Clear documentation is essential:

- Defined material grades

- Fixed colour codes

- Approved dielines and dimensions

Standardisation removes guesswork and reduces variation.

Use Approved Samples & Master Proofs

Consistency improves when every production run references the same benchmarks:

- Golden samples

- Print-approved proofs

- Material reference standards

These act as a constant point of comparison.

Work With a Long-Term Packaging Partner

A reliable packaging supplier UK businesses can trust will:

- Retain production history

- Maintain accountability across reorders

- Support forecasting and capacity planning

Long-term relationships reduce variation far more effectively than frequent supplier changes.

Role of Quality Control in Consistent Packaging

Quality control should be embedded at every stage:

- Incoming material inspections

- In-process checks during printing and cutting

- Final QA before dispatch

Consistent packaging is not accidental. It is engineered through process discipline.

Technology & Process Improvements

Modern production tools help stabilise output:

- Digital colour management systems

- Automated cutting and printing equipment

- Inventory and demand forecasting tools

Technology reduces human variability and improves repeatability.

Why Healey Packaging Delivers Consistency

Healey Packaging focuses on long-term reliability, not short-term output.

Our approach includes:

- Controlled material sourcing

- Colour-managed printing processes

- Dedicated account support

- Repeat-order consistency across production runs

- UK-based quality standards

As a UK-based packaging partner, we help brands maintain quality as they grow.

Let’s Talk Quality: Your Guide to Consistent Packaging

Use fixed colour specifications, approved proofs, and a supplier with colour-managed printing.

Yes. Long-term suppliers retain production knowledge and reduce variation.

In most cases, yes. Inconsistent packaging creates hidden costs that outweigh short-term savings.

Absolutely. With controlled sourcing and proper QA, sustainable materials can be highly consistent.

Conclusion – Consistency Is a Competitive Advantage

Consistency in packaging supply is not just an operational concern. It is a brand differentiator.

Reliable materials, stable colour, precise structure, and dependable reorders create trust with customers and partners alike. Brands that prioritise consistency reduce waste, protect their reputation, and operate more efficiently.

In a competitive market, consistency is not a constraint. It is an advantage.