Summary: Digital vs Offset Printing At a Glance

- ⚡Digital printing is fast, flexible, and ideal for short runs or personalisation

- 🎯 Offset printing delivers high-volume consistency and superior colour control

- 🔍 The best choice depends on your order size, budget, print detail, and customisation needs

- 🏷️ Healey Packaging offers both methods, tailored to your packaging goals

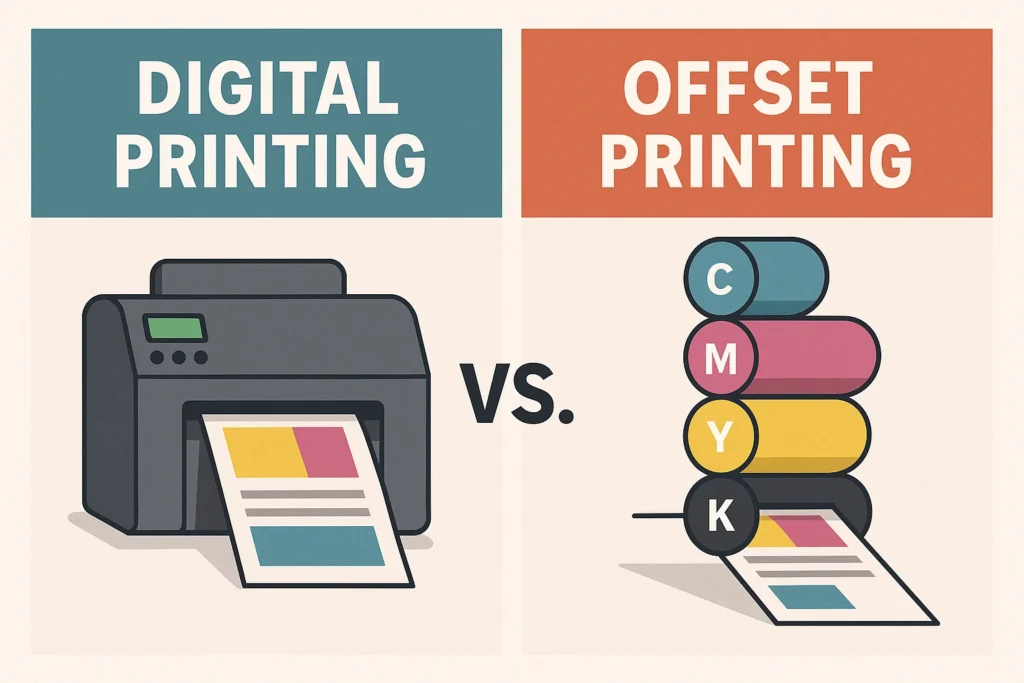

What is the difference between digital printing and offset printing?

Digital and offset printing are the two most common ways to add artwork to your packaging — but they work differently and suit different needs.

How does digital printing work?

Digital printing lets us take your design and print it straight onto the packaging — no plates, no delay. It’s quick to set up, which makes it perfect for smaller runs or one-off projects. You can even tweak the design on each box, which comes in handy for personalised packaging or limited-edition ranges.

How does offset printing work?

Offset printing uses metal printing plates and ink rollers to transfer your design onto boxes via a rubber blanket. It’s slower to set up, but once running, it’s fast, cost-efficient, and delivers exceptionally sharp, consistent colour output, especially for large orders.

Is offset printing better than digital?

It depends on what your packaging needs.

- Offset printing is better for large quantities, where colour matching and fine detail matter.

- Digital printing is better for small runs, tight deadlines, and personalised or seasonal box designs.

At Healey Packaging, we guide clients through this decision every day. For example, a luxury tea brand needing 10,000 boxes for national retail chose offset. But an artisan candle maker launching 300 holiday sets? Digital was faster, cheaper, and more flexible.

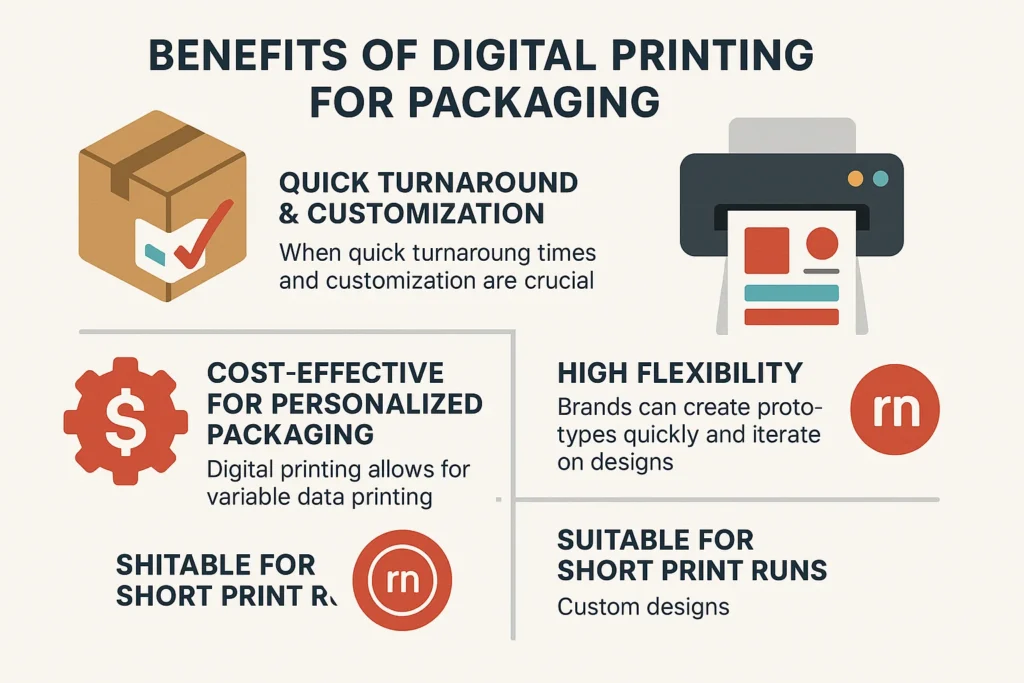

Which is a main advantage of digital printing over traditional offset printing?

The standout advantage of digital printing is speed and flexibility.

- No plate setup means same-day production in some cases

- Easily update artwork for A/B testing or product lines

- Low minimum orders make it startup-friendly

- Ideal for packaging with variable text like QR codes or individual customer names

This is why digital is often the go-to for e-commerce sellers, influencers launching product boxes, and anyone with frequently changing SKUs.

How can you tell if a print is offset or digital?

It’s not always obvious, but here are a few ways:

- Offset prints often feel smoother, especially on coated board. The ink sits within the paper, giving it a refined look.

- Digital prints may show tiny inkjet dots under magnification and sometimes a slightly raised texture on uncoated stock.

- Offset allows Pantone spot colours, while digital is almost always CMYK only

- If the colour is consistent across 10,000 boxes, it’s probably offset

At Healey Packaging, we’re happy to send print samples so you can see and feel the difference before placing your order.

When should you choose offset vs digital for your packaging boxes?

| Scenario | Recommended Method |

| 5,000+ boxes | Offset |

| 100–500 boxes | Digital |

| Fast turnaround | Digital |

| Exact colour matching (Pantone) | Offset |

| Variable data (e.g. names, codes) | Digital |

| Cost-effective per unit at scale | Offset |

Real-world tip:

If you’re testing a new product and not sure how it’ll sell, digital printing is a smart way to start. It keeps your costs low while you gauge demand. Then, once things take off, you can switch to offset for better value on larger orders.

What type of print does Healey Packaging recommend?

We don’t push one method over the other—we recommend what fits your product, timeline, and budget.

Example:

One of our skincare clients needed 250 printed boxes for a limited-edition product launch. We used digital printing with variable names and QR codes linking to tutorials. The boxes looked stunning, the launch was successful, and they later scaled the next run using offset for cost savings.

We also handle print file setup, advise on substrate choices, and offer FSC®-certified materials for both methods.

Expertise You Can Trust

Healey Packaging has supported UK brands with premium packaging since 2010. Our in-house print specialists and designers know the ins and outs of both digital and offset systems. We’re happy to help you:

- Choose the best printing method for your business

- Format your artwork for sharp print results

- Balance visual quality with production cost

- Order printed samples to compare results

We don’t guess—we guide.

Final Thoughts: Making the Right Print Choice for Your Brand

There’s no single “best” option — it really depends on what matters most to you. If you need something quick, flexible, or in a smaller quantity, digital printing makes sense. But if you’re aiming for consistent colours, bigger volumes, and better pricing per unit, offset is usually the better route.

Want to see the difference for yourself?

👉 Get a free quote or sample pack from Healey Packaging today. Let’s make your packaging unforgettable—whichever print method you choose.