TL;DR – Box Size Mistakes Are Costing Brands More Than They Realise

Choosing the wrong box size increases shipping costs, causes product damage, and wastes materials. Packaging boxes are measured using internal dimensions in the order length × width × height. Right-sized packaging improves protection, reduces dimensional weight charges, and supports sustainability, especially for eCommerce and retail brands shipping at scale.

Box size is one of the most underestimated decisions in packaging. Many brands focus on artwork, materials, or price, but box sizes and dimensions directly affect shipping costs, product protection, and how a brand is perceived.

Choosing the wrong size often leads to wasted space, higher postage fees, damaged products, and poor unboxing experiences. Oversized boxes increase dimensional weight charges, while undersized boxes can crush products or compromise presentation.

For eCommerce and retail brands, correct packaging box dimensions are not just a technical detail. They influence fulfilment efficiency, customer satisfaction, and long-term costs. Getting box sizing right from the start prevents recurring issues as order volumes grow.

What Do Box Dimensions Mean?

Packaging dimensions are typically expressed as:

Length × Width × Height (L × W × H)

This order is an industry standard and is used consistently across manufacturing, logistics, and courier pricing.

Internal vs external box measurements

- Internal dimensions measure the usable space inside the box

- External dimensions measure the outside of the box, including material thickness

Packaging manufacturers primarily work with internal dimensions, because they determine whether a product fits correctly. Couriers, pallet planning, and storage calculations often rely on external dimensions.

Understanding the difference prevents costly sizing mistakes.

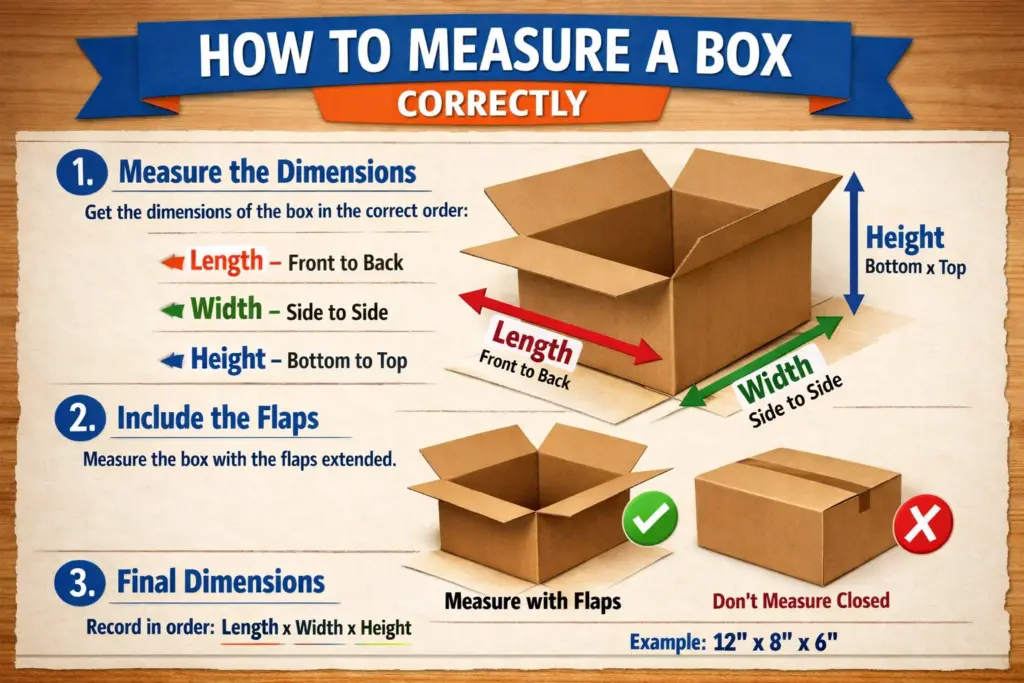

How to Measure a Box Correctly?

Measuring Internal Dimensions

To measure box size correctly, always measure the inside of the box:

- Measure length (longest side on the opening)

- Measure width (shorter side on the opening)

- Measure height (from base to top)

Record measurements in millimetres for accuracy. Internal measurements ensure the product, inserts, and cushioning fit without pressure.

Measuring External Dimensions

External dimensions matter when:

- Calculating shipping costs

- Planning pallet loads

- Managing warehouse storage

External size includes cardboard thickness, which can significantly affect volume for corrugated boxes.

Common Measurement Mistakes

- Mixing up dimension order

- Measuring the outside when internal size is required

- Ignoring material thickness

- Forgetting space for inserts or protective padding

These mistakes often result in boxes that technically “fit” but perform poorly in real-world shipping.

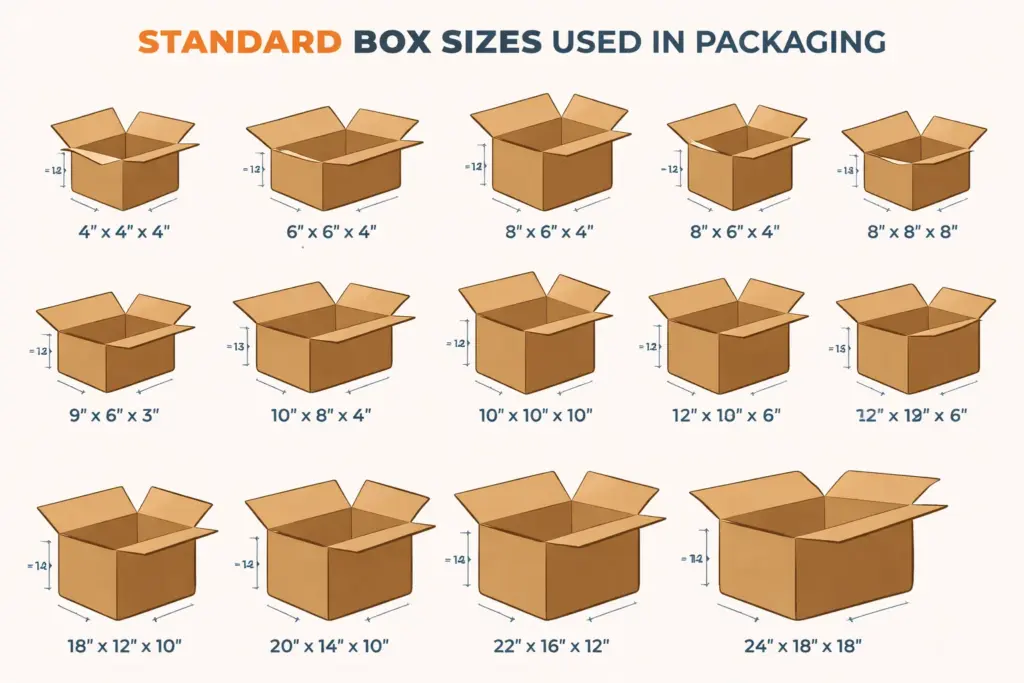

Standard Box Sizes Used in Packaging

While there is no single universal sizing system, standard box sizes UK suppliers use generally fall into these categories.

| Box Size Category | Typical Dimensions (Example) | Best For | Key Benefit |

| Small Boxes | 100 × 80 × 40 mm | Cosmetics, jewellery, accessories | Tight fit, minimal waste |

| Medium Boxes | 300 × 200 × 100 mm | Apparel, bakery items, subscription boxes | Balanced shipping & branding |

| Large Boxes | 600 × 400 × 300 mm | Electronics, bulk items, shipping cartons | Strength and stacking stability |

| Mailer Boxes | Custom-fit | eCommerce orders | Self-locking, efficient fulfilment |

| Custom Boxes | Product-specific | Retail & premium packaging | Reduced damage, lower shipping costs |

Note: Exact dimensions vary by material thickness and box style.

Box Sizes for Different Packaging Types

Mailer Boxes

Mailer boxes are popular for eCommerce because of their:

- Self-locking structure

- Flat-pack storage

- Easy assembly

Common shipping box sizes are optimised to fit courier size brackets and reduce dimensional weight.

Shipping Boxes

Shipping boxes are usually corrugated and chosen based on:

- Product weight

- Stacking requirements

- Transit distance

Correct flute selection and sizing prevent crushing and movement during transport.

Retail & Product Boxes

Retail packaging must consider:

- Shelf space

- Facing requirements

- Branding visibility

Box size directly impacts how products appear in-store and how many units fit on a shelf.

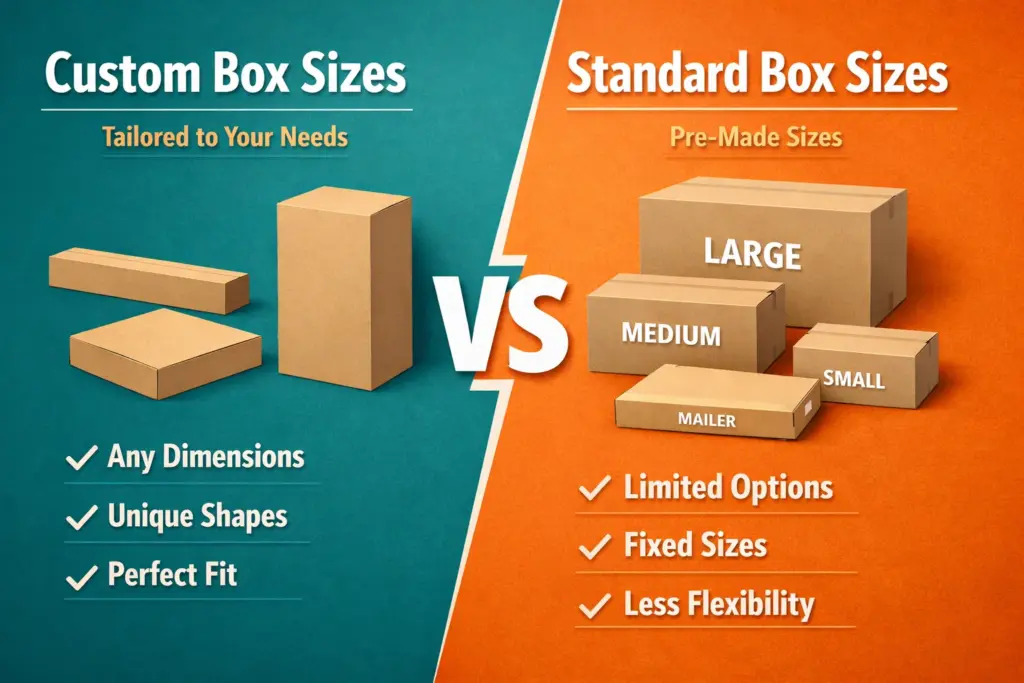

Custom Box Sizes vs Standard Sizes

When Standard Sizes Work Best

Standard sizes are suitable when:

- Products are uniform

- Volumes are high

- Speed and availability are priorities

They can be cost-effective for simple packaging needs.

When Custom Sizes Are More Cost-Effective

Custom box sizes often reduce overall costs by:

- Eliminating void fill

- Lowering shipping charges

- Reducing damage rates

They also improve presentation and brand consistency, especially for premium products.

How Box Size Affects Shipping Costs?

Courier pricing is heavily influenced by dimensional weight, which considers box volume rather than actual weight.

Oversized boxes:

- Trigger higher postage fees

- Waste pallet and van space

Right-sized packaging reduces shipping spend without compromising protection.

Box Dimensions & Product Protection

Correct box dimensions help by:

- Preventing product movement

- Allowing space for inserts and cushioning

- Reducing impact damage

Poor sizing is one of the leading causes of product damage during shipping, even when materials are strong.

Choosing the Right Box Size for Your Product

When selecting box dimensions, consider:

- Product size and weight

- Fragility

- Inserts or secondary packaging

- Storage and stacking requirements

A packaging size guide should always be built around the product, not convenience.

Box Size & Sustainability

Right-sized packaging supports sustainability by:

- Reducing material waste

- Lowering carbon emissions during shipping

- Minimising excess fillers

Custom sizing often delivers better environmental outcomes than oversized standard boxes.

Box Dimension Tips for eCommerce Brands

For eCommerce brands:

- Optimise sizes for fulfilment centre requirements

- Reduce returns caused by transit damage

- Improve unboxing consistency

Well-sized boxes improve both operational efficiency and customer perception.

Common Box Size Mistakes to Avoid

- Using oversized boxes “to be safe”

- Choosing boxes that are too tight

- Ignoring courier size limits

- Forgetting growth and reorder consistency

These mistakes scale quickly as order volumes increase.

Why Healey Packaging Helps You Choose the Perfect Box Size

Healey Packaging supports brands with:

- Expert sizing guidance

- Standard and custom packaging UK solutions

- High-quality materials

- UK-based production and fast delivery

Accurate sizing from the outset prevents repeat issues across future orders.

Getting Box Sizes Right: Common Questions, Clear Answers

Length × Width × Height (L × W × H).

Packaging is specified using internal dimensions unless stated otherwise.

Choose the smallest size that safely fits the product, inserts, and cushioning.

Not always. It often reduces shipping and damage-related costs.

Conclusion – The Right Size Saves Money & Protects Products

Correct box sizing is one of the most effective ways to control packaging costs, reduce damage, and improve customer experience. Understanding box sizes and dimensions helps brands make smarter decisions at every stage of fulfilment.

Whether you use standard sizes or custom packaging, choosing the right dimensions protects both your product and your margins.

Not sure which box size you need?

Healey Packaging offers expert guidance and custom box sizing solutions.

Request a Quote